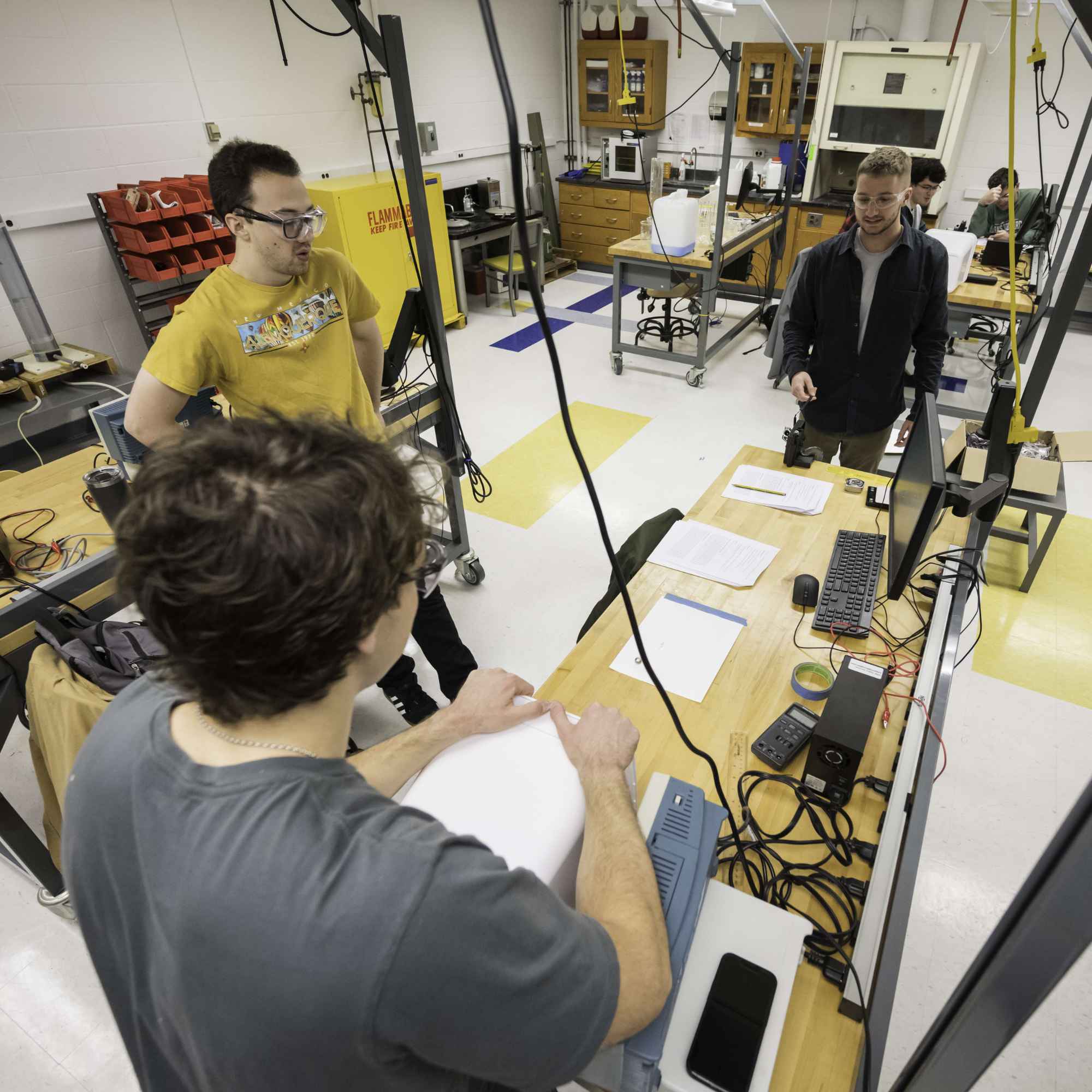

Faculty members work with industry advisors to modernize hands-on aspects of the department’s curriculum.

In Hopeman Hall, third-year mechanical engineering students barrage graphite paper repeatedly with small metal balls shot from spring-loaded launchers. The activity—part of Professor Douglas Kelley’s ME 240: Fundamentals of Instrumentation & Measurement class—looks fun, but it’s also teaching the students important lessons about repeatability and statistics.

“It’s good to get out of the lecture halls,” says Cole Senecal ’24. “The hands-on approach makes it a little easier to conceptualize some of the things we’re learning.”

The class is one of two upper-level lab courses—the other is Associate Professor Jessica Shang’s ME 241: Mechanics Laboratory—that the Department of Mechanical Engineering recently revamped to incorporate modern engineering methods and scale to meet growing enrollment demands.

“Our department has long been proud of the rigor and depth of our upper-level laboratory courses. But given the growth of engineering enrollment in our department and nationwide in the last decade, we wondered if it was time for an adjustment,” says Kelley.

Led by chair and fellow professor Renato Perucchio, the department consulted with its program advisory board composed of industry-connected alumni about ways to build a stronger foundation for students in applied engineering methods. The faculty agreed that existing labs were valuable and superior to many offerings elsewhere, so they didn’t want to make changes that compromised the quality of the curriculum.

By providing more structured courses and updating equipment, the department was able to strike a good balance of preserving what worked and freshening things up. The students are now using revitalized procedures and new gear including thermal cameras and thermocouples, microphones and ukuleles, launchers, strain gauges, amplifiers, motors, controllers, and data acquisition equipment.

“The entire overhauling process proved the importance of the interaction between our program advisory board and the faculty,” says Perucchio. “Their input during the initial stages of creating the new ME 240 lab course helped us quite a bit in selecting the labs and the experiments which would be consistent with the needs of modern industry.”

Kelley says the process was highly collaborative.

Professor Christopher Muir spearheaded the early process and brainstormed new equipment to include. Muir, Kelley, and Shang fleshed out ideas and identified lab exercises that fit the learning objectives, with input from colleagues including Assistant Professor Andrea Pickel, Assistant Professor Hesam Askari, and Senior Technical Associate Christine Pratt. Alexander Prideaux was hired to help finalize the lab procedures, build equipment, and make enough copies to run the course. Assistant Professor Anushika Athauda has been co-teaching the Fundamentals of Instrumentation & Measurement course since it was introduced in the spring.

Alejandro Porras ’25 says that he appreciates, in addition to the new equipment, how the faculty are incorporating their latest research into lab exercises.

“It was cool because for one of the labs in particle tracking, Professor Kelley gave us the code that he uses for his research,” says Porras. “We got some insight into what leading scientists are doing and what the field’s current research focus is.”

Kelley says it’s too early to tell how the revamped curriculum and equipment is benefitting students, but as they advance to senior design courses, any changes should become evident. Allison Thompson ’24, who took the first offering of the refurbished ME 240 course in the spring and is now serving as a teaching assistant, says the effort to continually improve the curriculum is evident.

“It’s interesting being on the other side of the class,” says Thompson. “In our meetings we’re able to see the mistakes people are making and try to find ways to help them improve. With it being a brand-new course last year, it’s nice to see how we’re continually trying to make it better.”

Read more

Lab experience your first year in college? Yes.

Lab experience your first year in college? Yes.

With faculty and graduate student mentorship, undergraduate researchers thrive in the Rochester Human-Computer Interaction lab.

‘Communicating Your Professional Identity’ flourishes at 10

‘Communicating Your Professional Identity’ flourishes at 10

Rochester students and alumni praise the decade-old course that teaches how to navigate the professional world.

Designing career paths for future mechanical engineers

Designing career paths for future mechanical engineers

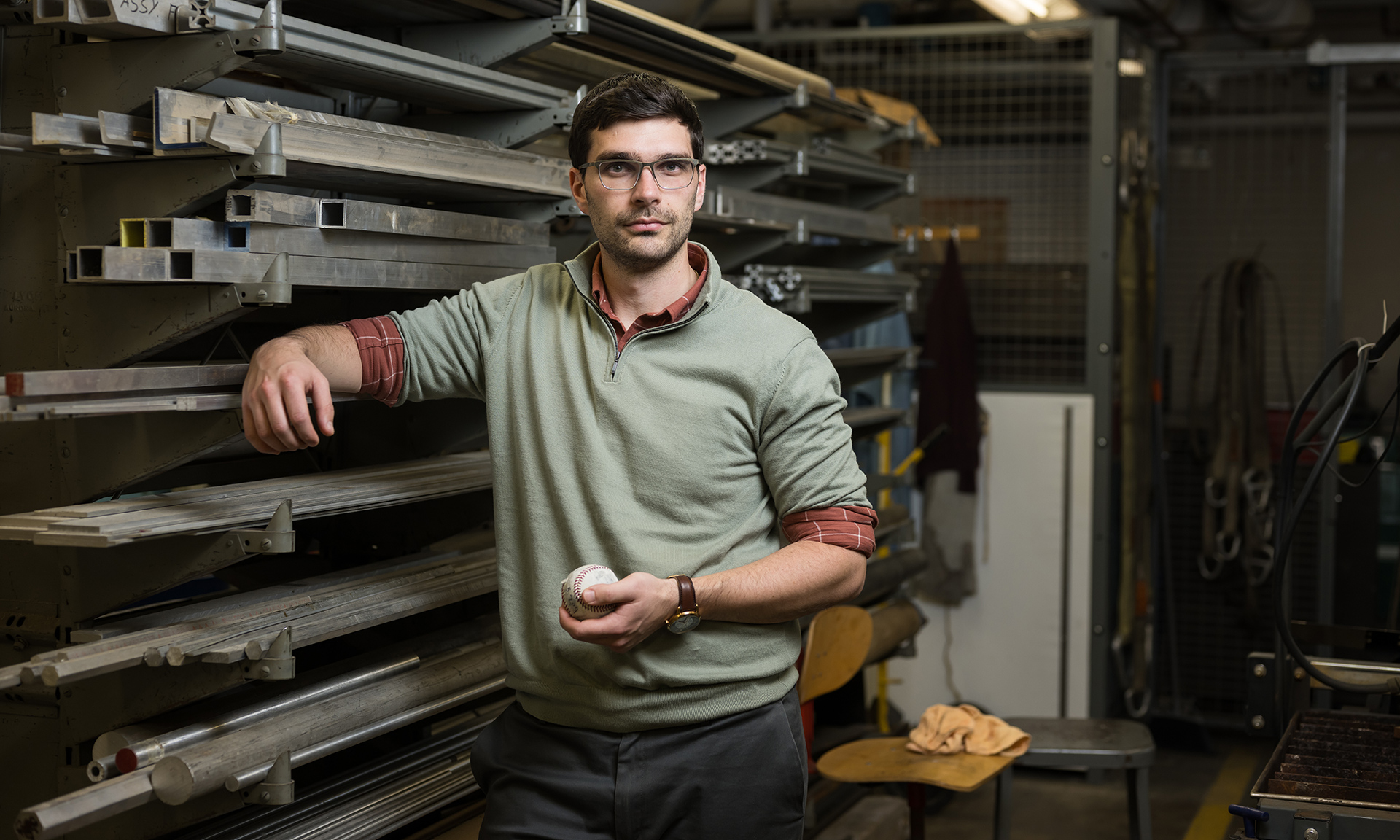

Engineering professor Christopher Muir draws from his vast experiences in the workplace to teach problem-solving mindsets.