Rochester undergraduates created tools and methods to reduce waste in the maple syrup industry.

In New York state, nearly 1 million gallons of maple syrup are produced every year, but one gallon of syrup is wasted for every 20 gallons produced.

This waste is mainly due to three problems: buddy syrup—caused by metabolic changes in sap, resulting in a cabbage-like taste and odor in the syrup; ropy syrup—caused by bacterial contamination during sap and syrup processing; and inefficient ways of measuring invert sugar levels, which affect ancillary products such as maple candies and creams. These conditions leave syrup unsuitable for human consumption and result in wasted energy, food, and resources, plus lost profits for sugarmakers.

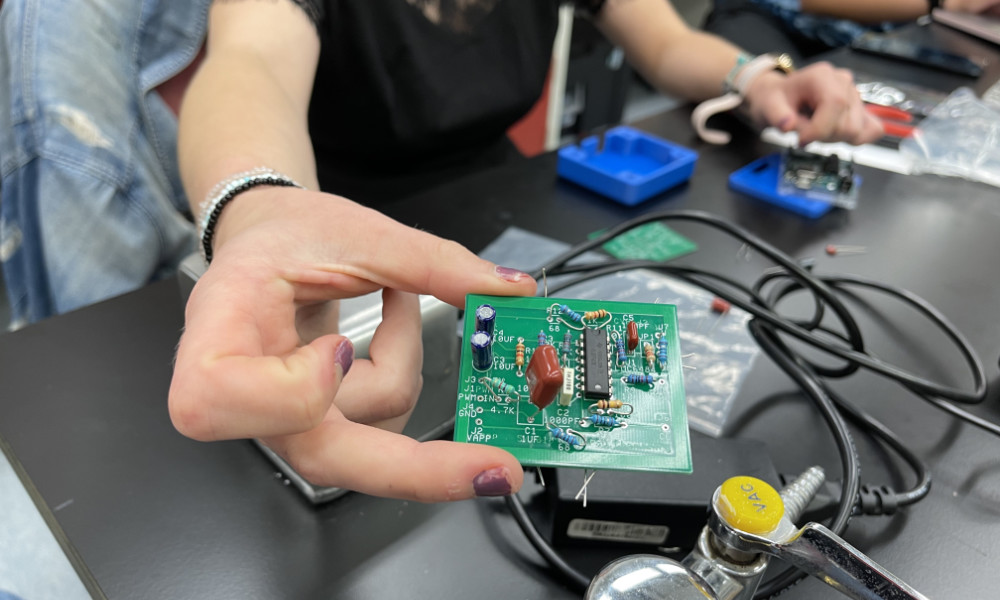

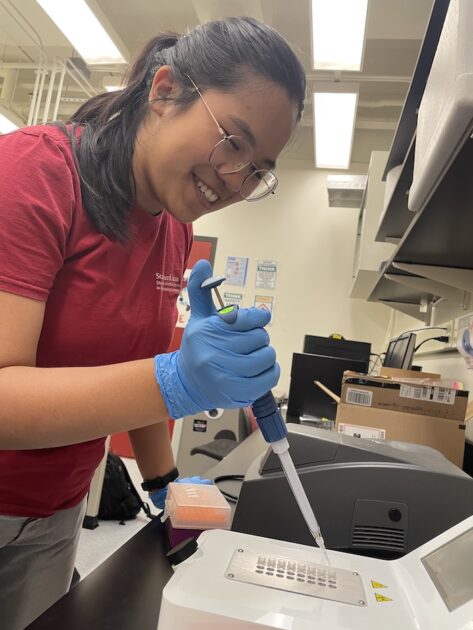

To address these problems, a team of 12 University of Rochester undergraduate students developed methods to detect and repurpose defective sap and syrup. Called “Team Saptasense” with the motto “saving syrup,” the students created new tools, including several novel biosensors and a glucometer, to help reduce waste in the maple syrup industry.

The team recently entered their research in the International Genetically Engineered Machine (iGEM) competition, where it was nominated for best hardware, best composite part, and best measurement awards and won a gold medal, making the team the second-most-awarded iGEM team in North America. The team competed against 356 other teams from six continents.

“The maple syrup industry is vitally important to our region’s economy as well as our culture,” says Anne S. Meyer, an associate professor of biology, and one of the advisors for Rochester’s iGEM team. “It is so exciting that our Rochester iGEM team was recognized at the competition for developing solutions to problems in the maple syrup industry. The awards they received are really a testament to the students’ hard work, creativity, and persistence throughout their project.”

From tree sap to maple syrup

Maple syrup is produced by extracting sap from maple trees in specific weather conditions and boiling it down to a sticky and sweet syrup. But it takes an incredibly large amount of sap to produce syrup: approximately 40 gallons of sap yield only one gallon of syrup.

In recent years, climate change has had notable effects on sap collection. In New York, for example, more frequent warm spells and increased average temperatures have shifted the window of time for sap collection and made syrup production unpredictable. Despite these challenges, the maple syrup industry has not been widely studied. The uncertainties surrounding climate change, coupled with the lack of scientific advancements in the industry, have exacerbated common syrup production problems.

Team Saptasense interviewed local sugarmakers and worked with the Cornell University Maple Research Program to better understand the problems in the maple syrup industry.

“Our team was inspired to find solutions to local problems,” says Carly Blair ’23, a molecular genetics major and member of the iGEM team. “New York State is the second largest maple producer in the United States, behind Vermont, so developing solutions to help maple sugar makers seemed like a natural choice for our project.”

The buddy syrup problem

As temperatures start to rise in the spring, maple trees begin to bud. The result is sap that has higher amounts of certain small molecules. If this “buddy sap” is boiled down to make syrup, the small molecules are more concentrated and the syrup has an unpleasant, cabbage-like flavor, rendering the syrup unsaleable. Unfortunately, maple syrup producers do not have a way to detect buddy sap until they have already used copious resources to process the sap into syrup.

“Currently the only thing producers can do to try to avoid producing buddy syrup is to pull their tree taps early, which can result in missed profits and is difficult for sugarmakers who tend large forests that are spread out across several climate regions,” Meyer says.

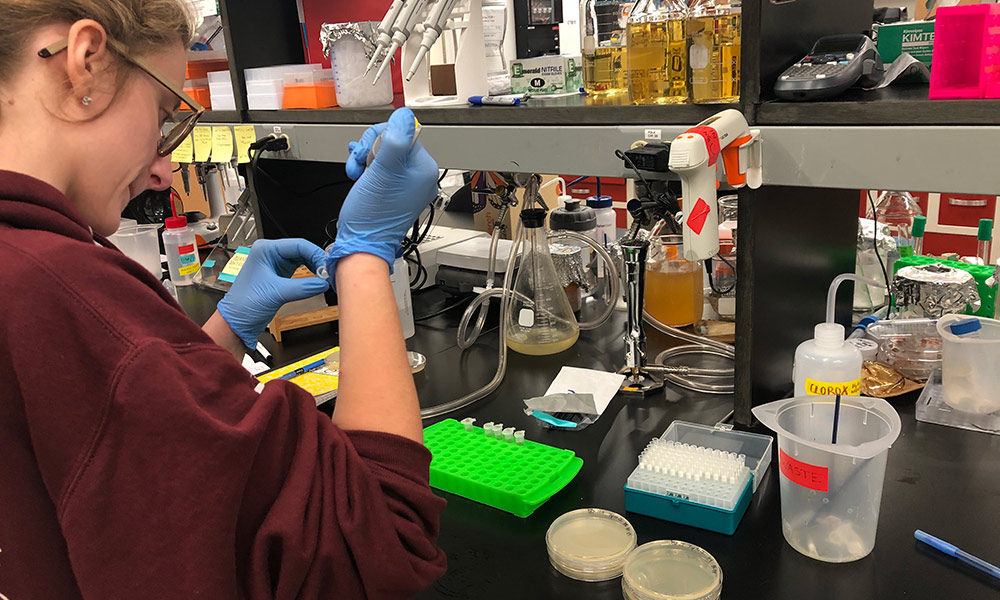

Team Saptasense designed three biosensors that use DNA technology to detect the molecules sarcosine, asparagine, and choline in sap. Sugarmakers can use these biosensors to determine if their sap is buddy, as it comes off the tree. If sugarmakers detect high levels of the molecules, they know the sap will be unusable.

“These cost-effective biosensors have huge potential to help prevent wasted time, money, and resources during the syrup production process,” says Sudarshan Ramanan ’25, a biology major and member of the iGEM team.

The ropy syrup problem

A second area the team addressed was the problem of “ropy” syrup. Normal syrup is viscous and forms droplets when it is pulled. When bacteria contaminate the syrup, however, the syrup can instead have a stringy, ropy texture. Ropy syrup is inedible and must be discarded.

Team Saptasense developed a new way for sugarmakers to convert their once-useless ropy syrup into a valuable product.

Ropy syrup has its distinct stringy texture because the contaminating bacteria have converted the sucrose in the syrup into polysaccharides—carbohydrates that consist of bonded sugar molecules—called dextrans. The team members demonstrated that dextrans can be purified from ropy syrup. They developed a new method to then turn the purified dextran into a robust, water-absorbent hydrogel that farmers can use to germinate seeds, while conserving water. Dextrans are also widely used in the medical field to treat hemorrhages and burns and aid in drug delivery and radiological imaging.

The invert sugar-level problem

Finally, while the iGEM team members were talking to sugarmakers about their project, they learned about another concern in the maple sugar industry. Many sugarmakers turn their sap and maple sugar into products such as maple candies and creams. Making these products requires precise measurements of the concentrations of glucose and fructose, collectively known as invert sugars. Because invert sugar levels affect the texture and flavor of maple products, sugarmakers need an accurate way to measure the concentration of invert sugars.

Sugarmakers typically measured invert sugar levels using commercial glucometers, which are designed to measure glucose levels in human blood for patients with diabetes. However, the levels of glucose in human blood are much lower than the glucose levels in maple syrup. As a result, sugarmakers need to dilute their syrup to read it in the glucometer. Diluting maple syrup is a challenge because syrup is thick and sticky, making it difficult to accurately measure its volume.

To help sugarmakers measure the levels of invert sugar in their syrup, Team Saptasense developed a new glucometer that they call the Saptameter, which has an increased detection range to measure invert sugar levels in undiluted maple syrup.

“This new piece of hardware will remove the tricky dilution step for sugarmakers, so they can make maple sugars and candies with the right texture and flavor every time, reducing food waste in the maple syrup industry,” Meyer says.

Community outreach

Outside the lab, Team Saptasense educated the community about synthetic biology through partnerships with local and national organizations including Rochester Museum and Science Center, Westside Farmers Market, Tutors For Change, and Highlands at Pittsford. In addition to designing engaging activities and experiments for K–12 students across the country, the team collaborated with other iGEM teams to author a children’s book about biology. The team also spearheaded inclusivity initiatives to promote disability justice in STEM, including a series of informative webinars and an accessibility self-evaluation form for professors at the University of Rochester.

Because iGEM is an open-source competition, the team’s work is documented and available on their Saptasense Wiki page. This format allows future students or developers to take up the designs of the devices the team created and build upon the team’s ideas.

“There are opportunities to further refine the research and development of the biosensors and functionality of the Saptameter in order to make the final product more accessible for sugarmakers,” Blair says. “Additionally, research into optimal storage conditions and shelf life of the biosensor strips would be necessary before the product could hit the market. We hope future groups will be inspired to build upon our research and conduct other research projects that aid the maple industry.”